Real-Time Visibility with Apptricity’s Asset and Inventory Tracking Software for Construction

Apptricity provides asset, inventory, and equipment tracking software. Our enterprise solution allows you to track, locate, safeguard, and streamline all your assets and inventory across multiple construction locations, providing you with real-time, operational visibility for your construction equipment.

Billions of Assets Tracked Globally

Trillions In Asset Value

Real-Time Visibility with Apptricity’s Asset and Inventory Tracking Software for Construction

Apptricity’s omnichannel inventory management solution is a comprehensive tool designed to help enterprises effectively manage their inventory across multiple channels. With features such as real-time inventory tracking, automated order fulfillment, and customizable reporting, Apptricity’s solution provides businesses with the visibility and control they need to streamline their operations and increase efficiency.

WHY APPTRICITY CONSTRUCTION EQUIPMENT TRACKING?

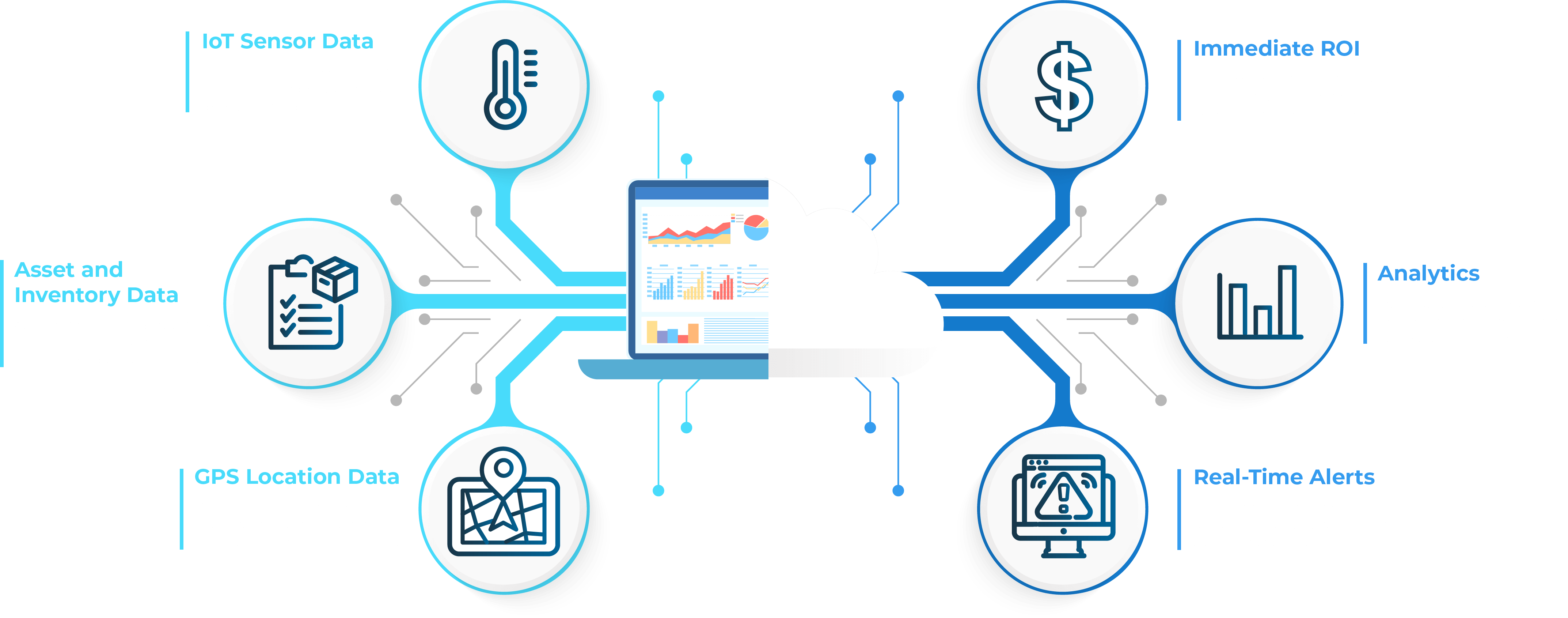

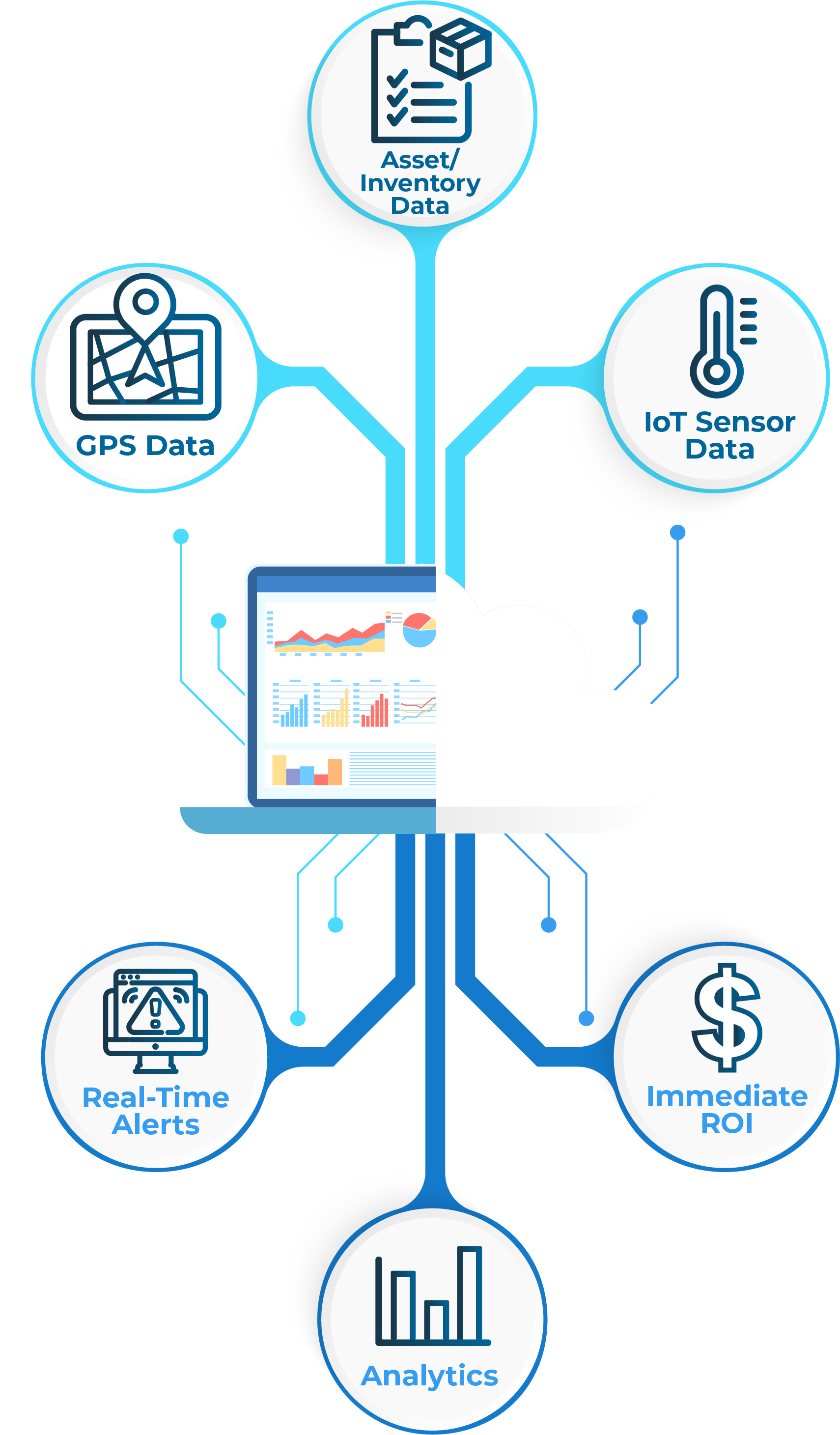

The Apptricity difference lies in our web and mobile software applications that integrate with the latest in IoT technology to provide a single solution for tracking and managing all your tools, machinery, equipment, inventory, and yellow iron.

Track high-value assets with GPS tracking tags

Full Equipment Maintenance History

Geofencing Alerts for Equipment on Construction Site

Track Tools and Equipment at each Construction Site

Automated Check-in and

Check-out Process for Construction Tools and Equipment

Full Asset Lifecycle Management

GPS Tracking for Construction Equipment

Real-time tracking is essential for managing the location of important equipment to maintain an on-time, on-budget project. Our construction equipment tracking software pairs with GPS tags that can be attached to any equipment, providing you with up-to-date location tracking. Tags can communicate via cellular or satellite, ensuring connectivity anywhere on your jobsite. With configurable ping rates, you can dictate the frequency of location updates by tag.

Automated Checkout and Ownership History for Construction Tool Tracking

Our automated checkout and ownership history features allow you to facilitate the process of checking out tools by scanning them and associating them with personnel. A complete ownership history ensures that you know who currently maintains ownership of the tool in case it fails to be returned. Custodians and end-users are managed at the individual item level, differentiating between who owns the tool and who is temporarily responsible for it.

Geofencing for Location Enforcement

Geofencing for location enforcement is another useful feature in our software. With Apptricity, you can establish boundaries around jobsites, alerting you if an item enters or leaves the boundary without authorization. Geofences can be built anywhere and in any shape, including the boundary of a building. Alerts are sent via SMS and email to ensure that you are notified if anything moves without permission.

HIGHLIGHTED USE CASE

Tools and Expensive Inventory and Equipment

Construction projects provide unique challenges in asset and inventory management due to a number of key factors, including the number of important tools and equipment that need to be managed, the size of the jobsite, and the importance of being on time and under budget. With Apptricity’s IoT-enabled, cloud-hosted Asset and Inventory Management solutions, users gain complete visibility into the location and condition of their tools and equipment. Applications for desktop, tablet, and mobile ensure that the solution moves in sync with the project, maximizing the value of assets and keeping projects under budget.

FAQS

Learn More about Apptricity for Construction

Can this solution be used for Construction Inventory Management?

Absolutely, in Apptricity terms, “asset,” “equipment,” and “inventory” are used interchangeably. The software and IoT tracking solutions we provide have the ability to streamline asset and inventory management processes for any industry. Specifically when it comes to Apptricity as construction inventory management software, the solution is just as comprehensive as mentioned above. In addition, we can tailor our software to meet your inventory tracking needs.

For example, getting real-time location data, automating cycle counts, and improving your check-in/check-out processes, we cut those times by up to 90%! Overall, Apptricity’s construction inventory management software provides a powerful tool for construction companies to streamline operations and always know where equipment and vital tools are located.

We have several vehicles across jobsites, can this be for construction fleet tracking?

Apptricity’s tracking software solution can be used for construction fleet tracking by pairing with GPS tags that can be attached to any equipment or vehicle, providing up-to-date location tracking. If you want to take it a step further, Apptricity’s I-Connect controllers can have GPS capability while also scanning onboard inventory for your fleet. Therefore, construction companies can get real-time visibility for all onboard, in-transit inventory as well. The software offers real-time tracking, full maintenance history, geofencing alerts on jobsites, and full asset lifecycle management, allowing construction companies to streamline their fleet management and make data-driven decisions for their construction projects.

What I really want is a construction tool tracking app, is that available?

Apptricity’s construction tool tracking app would simply be our software application that helps construction companies by offering automated checkout and ownership history features. This allows users to facilitate the process of checking out tools by scanning them and associating them with personnel. The mobile application can quickly scan a barcode via the camera on your mobile device and quickly update the software with whomever the item is assigned to. The software also provides complete ownership history, ensuring that users know who currently maintains ownership of the tool in case it fails to be returned. This feature helps construction companies keep track of their tools, reduce loss or theft, and ensure that their tools are being used efficiently.

I’ve seen you streamline maintenance and work orders, how does that apply to construction?

Apptricity’s construction equipment maintenance software provides full maintenance history and lifecycle management features for their equipment. The software allows users to track the maintenance history of their equipment, schedule maintenance tasks, and monitor the condition of equipment in real-time. By providing comprehensive maintenance management, Apptricity’s software helps construction companies reduce equipment downtime, extend the lifespan of their equipment, and reduce maintenance costs.

The solution enables construction companies to also streamline procurement processes, automate purchasing workflows, and manage vendor relationships. The software’s customizable dashboards and reports provide a comprehensive view of inventory levels, enabling agencies to identify trends, make informed decisions, and ensure they have the necessary resources to accomplish jobs more efficiently. With Apptricity’s construction tracking solutions you can gain real-time visibility, automate tedious tracking processes, and gain peace of mind.

Tell me more about the Apptricity GPS tracking device for construction equipment

Apptricity’s GPS tracking device for construction equipment can be attached to any equipment or vehicle to provide real-time location tracking. These devices communicate via cellular or satellite, ensuring connectivity anywhere on the jobsite. The GPS tags are configurable, allowing users to dictate the frequency of location updates and adjust them according to their needs.

The GPS tracking devices are designed to withstand harsh environments and extreme temperatures, making them suitable for construction site conditions. They are also rugged and durable, ensuring that they can withstand the wear and tear associated with the construction industry.

Apptricity’s GPS tracking devices can be integrated with our web and mobile software applications, providing a single solution for tracking and managing construction assets and inventory across locations. This integration ensures that users have access to real-time tracking data, full maintenance history, geofencing alerts on jobsite, and full asset lifecycle management features.

By using Apptricity’s GPS tracking devices, construction companies can optimize their fleet management, reduce equipment loss or theft, and make data-driven decisions based on accurate and up-to-date location data. Overall, Apptricity’s GPS tracking device for construction offers a comprehensive solution for construction companies looking to streamline their asset and inventory management processes.

Why is Apptricity the best asset tracking software for construction?

As stated earlier, in Apptricity terms, “asset,” “equipment,” and “inventory” are used interchangeably. With this in mind, Apptricity is considered the best asset tracking software for construction because of its accuracy, reliability, and ease of use. Trusted by the US Army, US Air Force, Verizon, Brinks, Komatsu, Olson Steel, construction companies across the country, and more Fortune companies, Apptricity leverages a combination of Bluetooth® Low Energy (BLE) beacons, patented edge devices, and proprietary software to provide real-time tracking of assets and inventory. Apptricity’s system boasts up to real-time location tracking, which is critical for construction companies needing to track assets, inventory, and equipment. Additionally, the system can be easily integrated with other enterprise systems, such as enterprise resource planning (ERP) to provide a comprehensive solution for construction equipment tracking. Overall, Apptricity’s Construction Equipment Tracking software solution is a top choice for construction companies looking to improve their tracking capabilities.

Contact Us Today For More Information

APPTRICITY TECHNOLOGY

We know IoT technology and use it to make construction asset management operations easier, in turn, making your job and life easier

GPS Asset Tags

These tags connect to the internet via cellular or satellite and communicate GPS coordinates in up to real-time. Perfect for tracking items such as yellow iron, power generators, and other types of heavy machinery across any large jobsite.

Apptricity I-Connect Controllers

Apptricity’s edge devices are deployed with RFID and/or Bluetooth® antennas to scan nearby tags and update their location in the Asset Management solution. These fixed readers can be set up in warehouses, tool trailers, or any other enclosed areas, including vehicles.

Bluetooth® Beacons

RFID Tags

SOLUTION SPOTLIGHT

These are some of the top solutions that bring our construction clients the most ROI

GPS Asset Tracking

Associate GPS asset tags with important construction assets to provide real-time tracking services. Assets can then be viewed on the map within the Apptricity Asset Management software application. Regardless of where your assets travel, you can pinpoint their exact location on the map.

Inventory Tracking

For places like warehouses, tool trailers, and storage facilities, an Inventory Tracking solution provides real-time insight into the location and quantity of important inventory items. Cycle counts can be completed in minutes, and alerts can be generated if quantities fall below a certain threshold.

Enterprise Asset Management

Apptricity’s EAM application helps users track and manage the entire lifecycle of their important construction assets. With an integrated maintenance, ownership, and usage history module, users always have access to the important information about their tools and equipment.

BENEFITS OF INTEGRATING IOT TECHNOLOGY

© Copyright Apptricity Integration Engine 2001

BENEFITS OF INTEGRATING IOT TECHNOLOGY

© Copyright Apptricity Integration Engine 2001

OUR CUSTOMERS

Apptricity is trusted by the largest Government and Commercial Organizations in the world.

The leader in global real-time asset management, Apptricity provides continuous asset tracking and supply chain solutions with the most secure, accurate, and dependable asset monitoring and data intelligence available. We place our clients at the center of all we do, providing them with uninterrupted global access to mission critical information in real time.

North America - Texas

220 E. Las Colinas Blvd Suite 400

Irving, Texas 75039, USA

Toll-Free: 800-693-2193

+1-214-596-0601

+1-214-596-0609

info@apptricity.com

North America - California

15635 Alton Parkway

Suite 420

Irvine, CA 92618

+1-323-823-6700

info@apptricity.com